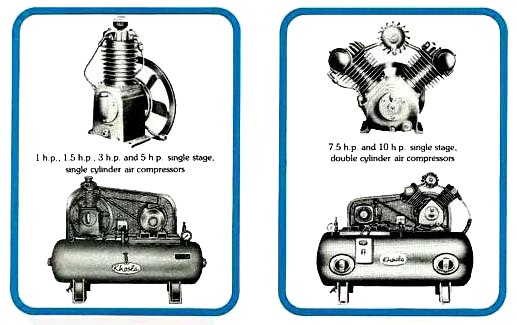

Lub. Air Compressors

Crankcase: the pressure tight crankcase is of a high grade iron casting. It is provided with an oil indicator and oil drain plug.

Crankshaft: statically and dynamically balanced crankshaft with counter-weights as integral pan ensure balanced and smooth operation The bearing surface are extra-large and precision-ground to size.

Cylinders: Are bored and honed with precision to give glass smooth finish to reduce friction, wear And tear. Cylinders are separate and detachable from the crankcase for easy access for cleaning, inspection and servicing.

Pistons: are matched for smooth vibration free operation and are fined with oil control and compression things of finest quality which ensure maximum delivery of clean air, Short piston strokes and slow piston speeds reduce heat generation by friction and decrease power loss.

Valves: Strip valves open and close very quickly which result in high efficiency.

Suction air filter: Easily removable for periodical cleaning. It has a dual purpose of cleaning air and to muffle air intake noise.

Flywheel: Well-balanced flywheel ensures vibration free and smooth running of the compressor and also acts as a fan for effective cooling of the cylinders and as inter cooler for double stage air compressor.

Vee-bell drive: Makes alignment easier for smooth, noise-free and efficient operation.

Automatic pressure switch: This switch starts and stops the motor of the air compressor when desired pressures are reached.

Lub. Air Compressors

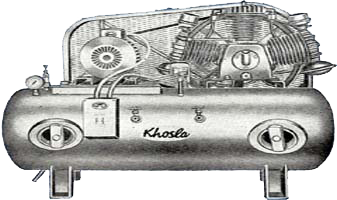

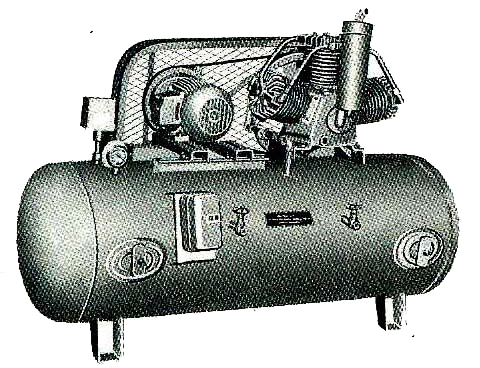

Khosla air compressors are engineered for economy, long life and easy operation and are product of over 3 decades

of research, development and manufacturing experience. These are reciprocating, air-cooled machines, renowned for durability and dependability, and are available: bare unit or complete with air receivers, with or without prime movers, which can be electric or petrol or diesel engines.

These compressors can be mounted on base plates, skids or on trolleys. They can be supplied with standard accessories such as pressure gauge, safety valve, non-return valve, automatic pressure switch, side rails, suction air filter, vee belt and belt guard.

Oil Free Air Compressors

Khosla oil-free compressors are engineered for economy, long life and easy operation and are products of over three decades of our research, development and manufacturing experience. These are reciprocating air cooled machines renowned for durability and dependability.

use of oil is completely eliminated.

Piston rings and guide rings are made of teflon which do not require any lubrication

Cylinders are mirror finished by honing.

Valves are made of special steel.

Constructional features

Crankcase:

The pressure tight crankcase is of high grade iron casting.

Crankshaft

Statically and dynamically balanced crankshaft with counterweights as integral part ensure balanced and smooth operation. The bearing surfaces are extra large and precision ground to size.

Cylinder:

Bored and honed with precision to give glass-smooth finish to reduce friction,wear and tear.Cylinders are seprate and detachable from the crankcase for cleaning,inspection and servicing.

Piston:

Matched for smooth and vibration-free operation. Fitted with teflon ring of finest quality which ensure maximum delivery of clean air.Short piston strokes and low piston speeds reduce heat generations by friction and decrease power loss.

Valve:

Strip valve opens and closes quickly which results in high efficiency.

Flywheel cum fan:

Well balanced flywheel ensures vibration-free and smooth running of the compressor and also acts as a fan for effective cooling of the cylinders.

The compressors are supplied with following standard accessories:

(a) Automatic pressure switch (b) Belt guard (c) Pressure gauge (d) Safety valve (e) Non-return valve (f) Drain cock (g) Suction air filter (h) Air receiver.

| Model | CT4.5 | ECT7.5 | ECT10.5 | ECT17.5 | 2ECT30 | 2ECT35 | |

| Power | h.p. | 1 | 2 | 3 | 5 | 7.5 | 10 |

| Piston displacement | Iil/min | 127 | 212 | 297 | 496 | 850 | 991 |

| cim | 4.5 | 7.5 | 10.5 | 17.5 | 30.0 | 35.0 | |

| Pressure | Kg/cm2 | 7 | 10.5 | 10.5 | 10.5 | 10.5 | 10.5 |

| Psig | 100 | 150 | 150 | 150 | 150 | 150 | |

| Speed | r.p.m. | 450 | 335 | 475 | 750 | 650 | 750 |

Vacuum Pumps

Khosla vacuum pumps are latest in design and simple in operation. Khosla vacuum pumps are positive displacement piston type air-cooled pumps which achieve up to 27” of Hg(686mm).

No foundation:

Further, these machines do not require any foundation as they are vibration free. The base frame mounted machines can be just put on a normal level floor. Thus, for putting the machine in operation, only electric connections are to be made.

No water connection required:

Unlike rotary water ring type vacuum pumps, no water connections are required for Khosla vacuum pumps. No water comes in contact with the moving parts, and they are good for many years, whereas in rotary water ring vane type vacuum pumps, the vanes get corroded within a couple of months of operation.

Salient features

Choice of drive: Electric/Diesel:

Pumps can be supplied duly coupled with either electric motor or diesel engine. (However for diesel engine driven unit, foundation will be required).

Automatic start-stop:

Automation vacuum switches can be provided for automatic cut in and cut off electric motor when a preset vacuum has been reached.

Easy to clean filter:

Pumps can be provided with effective inline replaceable suction filter which can be cleaned when it gets dirty.

Low power consumption:

Pumps are highly efficient with a few moving parts. They consume less power.

Low noise level:

Specially designed exhaust muffler reduces noise level to a very low pitch.

Low lubricating oil consumption:

The efficient oil scraping system does not allow air to carry any oil.

Application:

Khosla vacuum pumps are ideal for hospitals, paper industry, Food processing units, vacuum forming. Liquid transfer and numerous other applications.

| Model | Piston Displacement | Motor h.p. | |

| Single Stage | Iit/min | cim | |

| VE 11 | 312 | 11 | 1 |

| VE 20 | 566 | 20 | 2 |

| 2 VE 40 | 1133 | 40 | 3 |

| 3 VE 60 | 1698 | 60 | 5 |

| Two Stage | |||

| VEA 20 | 566 | 20 | 2 |

| 2 VEC 40 | 1133 | 40 | 3 |